TYPES OF GRATINGS:

- E.A.F. primary off-gas

- L.F. primary off-gas

- E.A.F. secondary off-gas (canopy hood)

TYPES OF GRATINGS:

- Industrial floorings - Maintenance Walkways

- Drain covers - Drainage

- Compound walls

- Light traffic access ramps and disable access ramps

- Vertical cladding in architectural application

- Stairways and Catwalks

- Marine Industries

- Tower Packing Support

- Power Plant

- Stair Treads

Advantages of Gratings:

- Corrosion Resistant

- Fire Retardant

- High Impact Strength

- Easy to Install

- Light weight

- Safe

- In serration notches made on tip of the loadbearing bar improve skid resistance

Product Portfolio

We offer varied range of durable castings, which are manufactured with the use of superior and innovative manufacturing techniques.

Our range includes the following:

- Steel Gratings

- Electro Forged Steel Gratings

- Manual Steel Gratings

NOMENCLATURE OF GRATINGS PRODUCT SPECIFICATIONS:

BEARING BAR OR LOAD BEARING BAR (BB):

These bars support the load put on the grating and they are made from low carbon steel grade 152062.

MESH:

It is the center distance between two adjacent bearing bars and cross bars.

CROSS BAR (CB):

They are positioned transversely across bearing bars and are welded into them at the interaction point to provide lateral restraint. In steel Gratings, these are made of square twisted wire road from low carbon grade steel of SAE1008.

EDGE BINDING OR FRAME BAR (FB):

Bar fixed to the edge of the gratings and flush with the top of bearing bar.

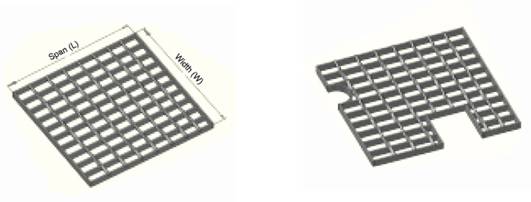

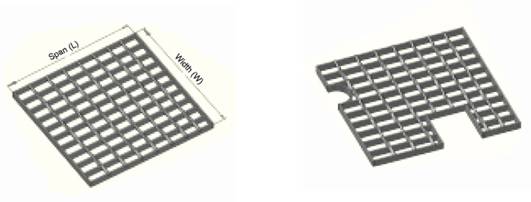

SPAN (S):

Total length between the supports, i.e. the extreme ends of the bearing bars. It is measured parallel to the bearing bar. (Length of the load bearing bar)

WIDTH (W):

It is the overall width of the panel measuring 90° to the load bearing bar.

CUT OUTS:

The area of the gratings removed to allow structure, Pipe, Plant, Obstruction or handrail to be fitted in.

PRODUCT SPECIFICATIONS (ALL UNITS IN MM)

Bearing bar sizes (Plain or Serrated):

25 x 3, 25 x 5, 30 x 3, 30 x 5, 32 x 5, 40 x 5, 50 x 5, 60 x 5 and 70 x 5

Cross Bar sizes:

6 & 8 Square Twisted

Mesh sizes:

Bearing Bar Pitches 30/33/35/40/41

Panel Sizes:

5000, 5700, 6000, 6100

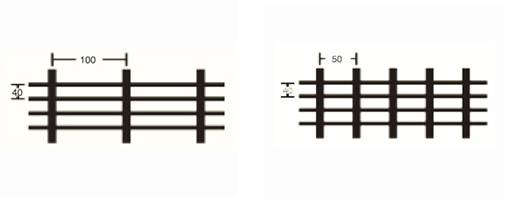

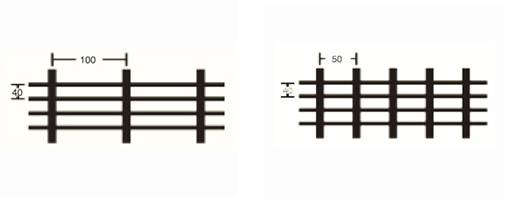

RECTANGULAR PATTERN

RECTANGULAR PATTERN

Most commonly used grating having bearing bar space C\C 40mm and cross bar spaced at C\C 100mm. Having bearing bar spaced at C\C 40mm and cross bar spaced at C\C 50mm

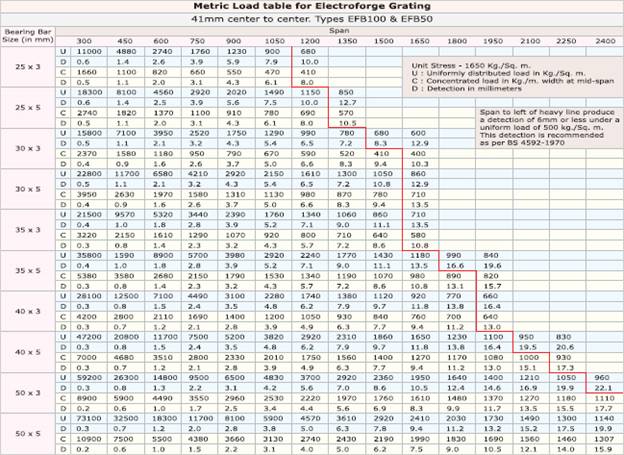

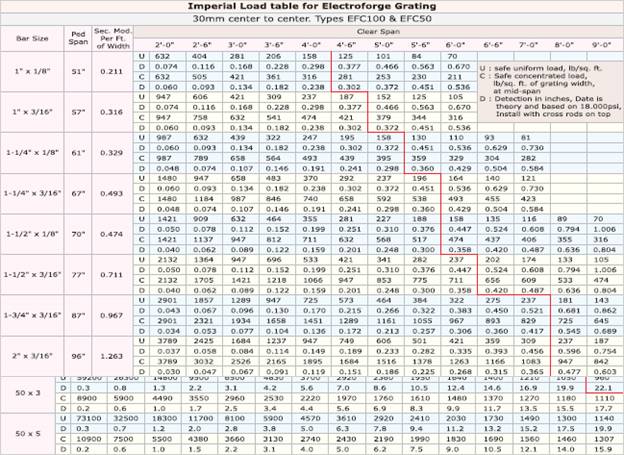

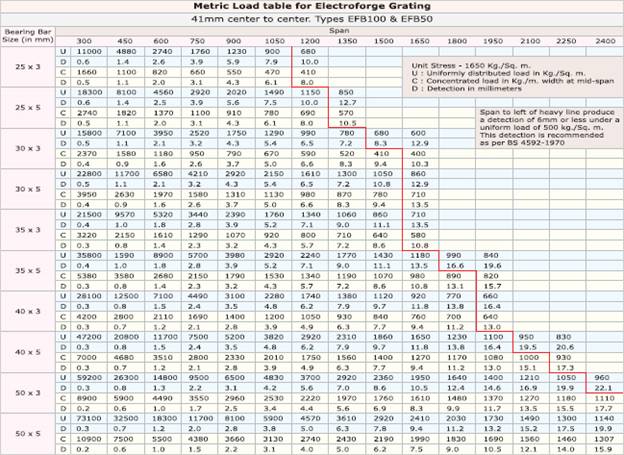

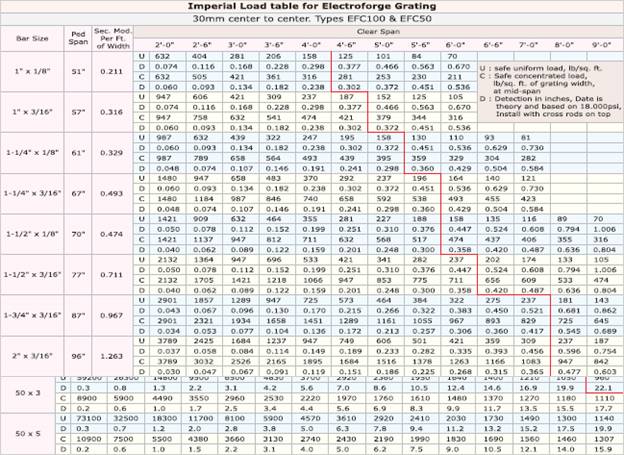

Electro forged Gratings

Electro forged Gratings

Electro forged bar grating is forge-welded. In this process the bearing bars and cross rods are permanently forged together by heat and pressure into a single unit construction, resulting in greater strength per pound than mechanical assembly methods. The twisted cross rods provide a non-slip walking surface. For applications where extremely slippery conditions prevail, Serrated Gratings offers a superior grip surface to the load bearing bars.

Electro forged grating is the most popular product. Nearly all sizes in Standard Mesh Type are readily available in our warehouses. Simplicity in design is surpassed by its versatility in usage. From mezzanines, platforms, catwalks, and stairs to fences, benches, racking shelves, and ventilation covers, Electro forged Steel Bar Grating is by no means limited to the industrial applications for which it was originally designed. Available in bare steel, shop primed, or hot dip galvanized.

Circular Gratings

Circular Gratings

Circular Gratings are manufactured from ready Electro forged Grating Panels. We prepare layout as per Equipment Platform drawing after making frame we cut the Panel as per Grating Frame size and do the welding. Circular type Gratings are strictly made as per Equipment platform drawings under strict supervision to avoid any issue during erection. Pipeline Cut outs, Platform Erection Bolt Cut outs and Notching for Structural Sections are also made. Every Gratings are marked with Platform Number and Grating number with hard Punching.

Drain Gratings

Drain Gratings are used to cover Storm Water, Rain Water drainage in Plant and in open areas. Drain Gratings are manufactured as per the size of Drainage Channels, Catch Basins, Point Drains, Trench Pits covers, and Manhole Covers. Drain Gratings also provided with side Angle support or plain as per the client requirements in MS, SS, Galvanized or Painted condition. Custom Drain/ Trench Gratings supplied in light duty for application where only foot traffic or light vehicular traffic will be seen. For heavy rolling load like forklift, cars and truck movement heavy duty steel gratings are recommended.

Tank Threads and Landings

Grating Stair Treads are manufactured with the best quality and workmanship in Plain Rectangular, Trapezoidal shapes with Side Carrier Plate and With Antiskid Nosing as per requirements. These are primarily installed by bolting or welding on Industrial and Commercial Stairs or around vessels or on Tanks. All stair treads are custom fabricated to meet the size, width and length specifications of a particular job. In addition, standard end plates can be custom fabricated to meet special bolt hole size or location requirements.

Stainless Steel Gratings

We Supply Stainless Steel Gratings which are durable, impact resistance, can stand up to extreme conditions involving high temperature and harsh chemicals. Stainless Steel Gratings are easy to clean and maintain and do not rust mainly used in Chemical, Dairy, Pharmaceutical, Food Industries as per client requirements. SS Gratings manufactured in SS 304, 308, 316, 316 L, from reputed make Plates. Gratings are fabricated from SS Plates after shearing in correct sizes to achieve quality finished material. Finishing of Fabricated Gratings are done by Acid cleaning or polishing.